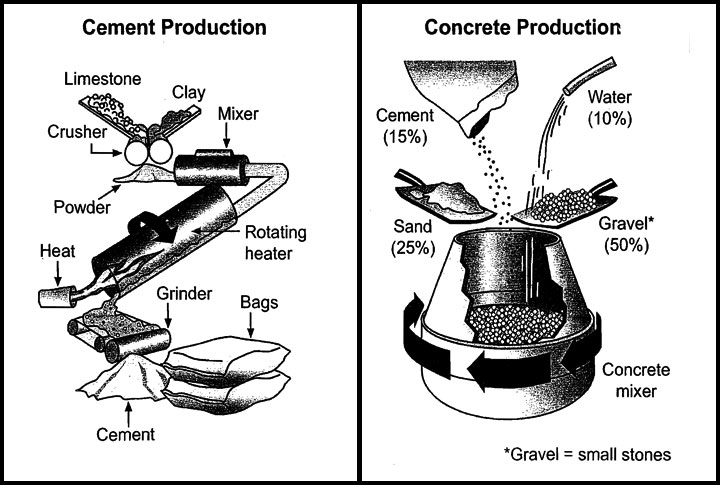

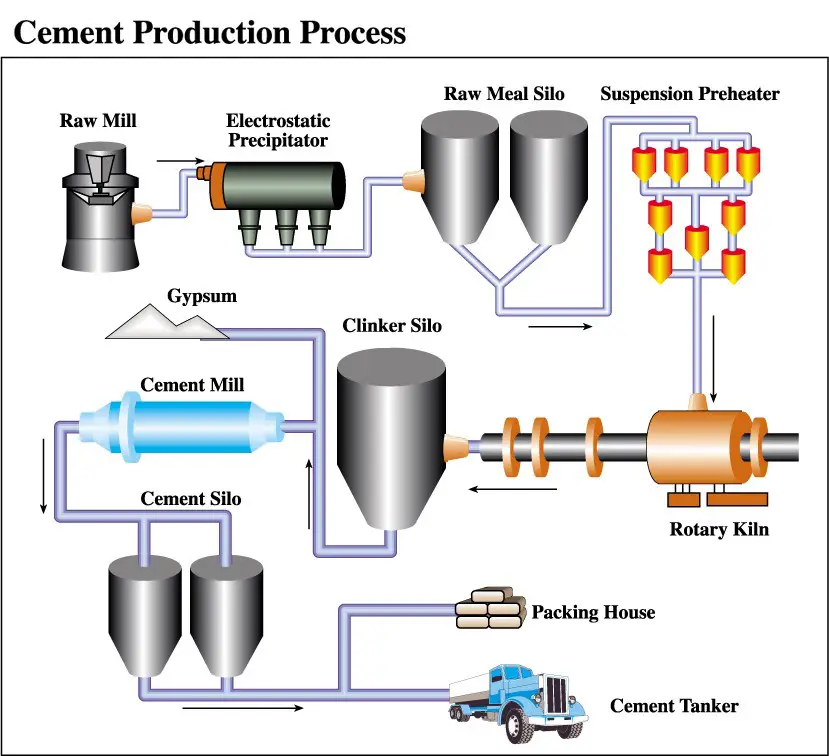

The type of batching, volume or weighted, is contingent on the amount of concrete being produced. The first step involves gathering the ingredients necessary to produce the particular type of concrete. We put together this basic overview of the manufacturing process to provide a high level view of the tasks at hand. Concrete Manufacturing Processes Overview Cast in molds and hardened in a controlled environment, different types of precast concrete include stairways, poles or blocks. This type is not identified by the materials used to create it but rather its shape and preparation before it is brought to a job site. This type was designed to have high tensile strength for maximum durability in erecting bridges and other weight bearing structures. Regarded as the “most important” type, reinforced concrete is identified by its integrated steel reinforcements by way of bars, rods or mesh. This is most commonly used in structures with high levels of radiation, is composed mainly of high density crushed rocks and is identified as having density levels between 3000-4000 Kg/meter.cube. This type is particularly resistant to freezing and thawing. This is a form of plain concrete infused with thousands of air particles created by infused foam or other chemical agents. This is most commonly used to protect steel structures and for thermal protection, it can be composed of a variety of materials like pumice, clay or perlite and is identified by having a density less than 1920 Kg/meter.cube. This is most commonly used in the construction of buildings and roadways, plain concrete is composed of the traditional mix of cement, sand, gravel and the proportionate amount of water.

Types of Concreteīefore we dive into the manufacturing process and safety concerns, here is a brief recap of some common types of concrete.

With this in mind, we put together a basic overview of the concrete manufacturing process, along with highlighting potential safety risks and safety gear to consider.

MCR Safety understands the intricacies of the industry and the safety gear required to protect laborers. While innovation has helped humankind build great structures like the Hoover Dam, many age-old safety problems and concerns still loom. The evolution of today’s concrete industry has grown into a multitude of concrete types, ranging from plain to reinforced concretes with embedded steel bars and rods. Today it involves advanced chemistry to create the compounds which makeup modern day structures and roadways. A craft that began as a basic mixture of crushed stone, sand, and water in early civilizations has evolved into a complex industry, making up approximately 10% of US domestic gross national product. The manufacturing of concrete has come a long way since its days of crushed and burned limestone.

0 kommentar(er)

0 kommentar(er)